Product Center

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

Search the whole station

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

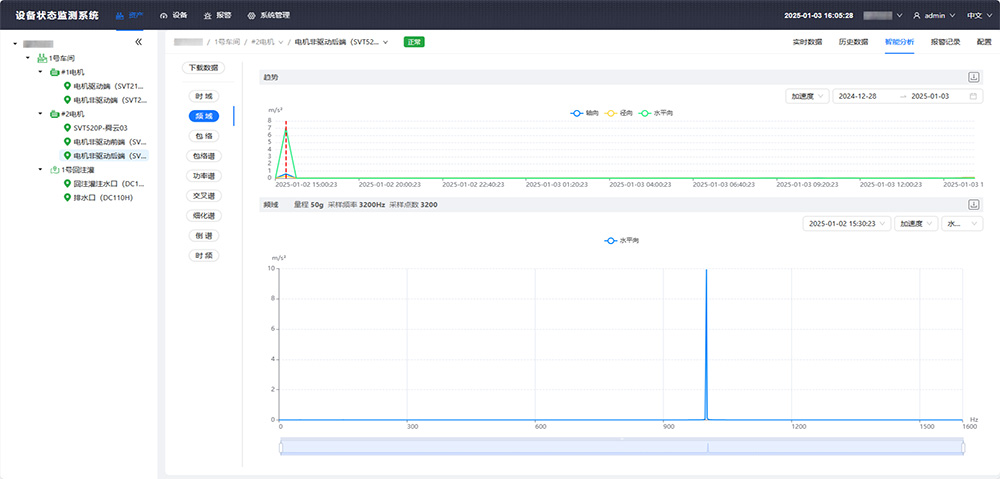

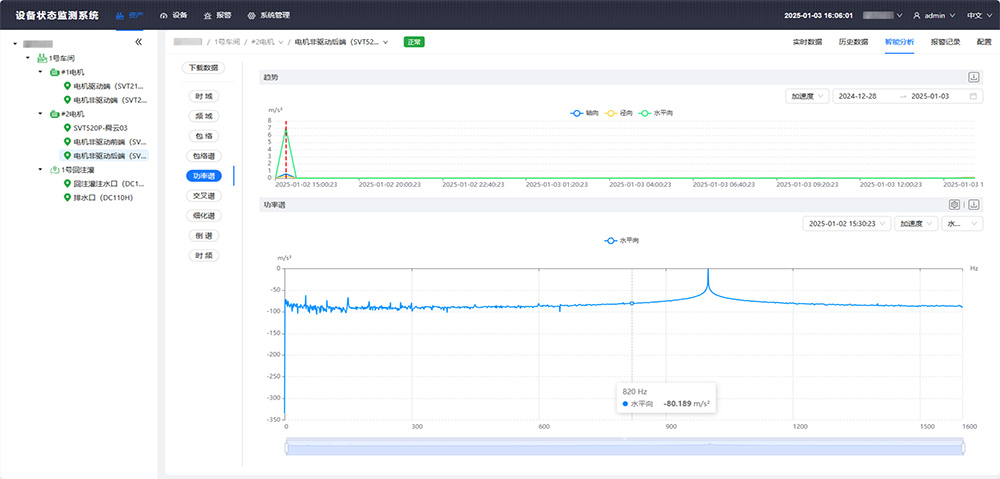

The Theta Equipment Condition Monitoring & Diagnostic System is an industrial software platform designed for real-time health monitoring of rotating machinery and critical equipment. Integrating IoT technology, vibration analytics, data visualization, and predictive maintenance capabilities, the system uses high-precision sensors and an advanced analytics engine to help industrial enterprises perform accurate condition assessment and fault prediction.

Imbalance, looseness, misalignment

Inner/outer ring damage, rolling element wear

Poor meshing, pitting, gear cracks

Rotor eccentricity, winding short circuit, stator looseness

Misalignment, tension issues, belt wear

Angular misalignment, parallel misalignment in couplings

Theta’s Equipment Condition Monitoring & Diagnostic System delivers intelligent, automated asset management tailored for industrial operations. By combining accurate data acquisition, vibration analysis, and fault diagnostics, the system helps enterprises reduce failure risk, improve equipment utilization, optimize maintenance costs, and enhance overall operational efficiency.

Submission