Product Center

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

Search the whole station

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

The Theta Corrosion Monitoring System is an intelligent monitoring platform designed specifically for corrosion assessment in pipelines and vessels within the oil, gas, and chemical industries. Built on IoT architecture and compatible with both Linux and Windows operating systems, the system supports browser/server (B/S) data access. It integrates sensor networks with analytical software to monitor corrosion conditions in real time—helping users gain a full understanding of asset health, optimize maintenance strategies, and enhance equipment safety and service life.

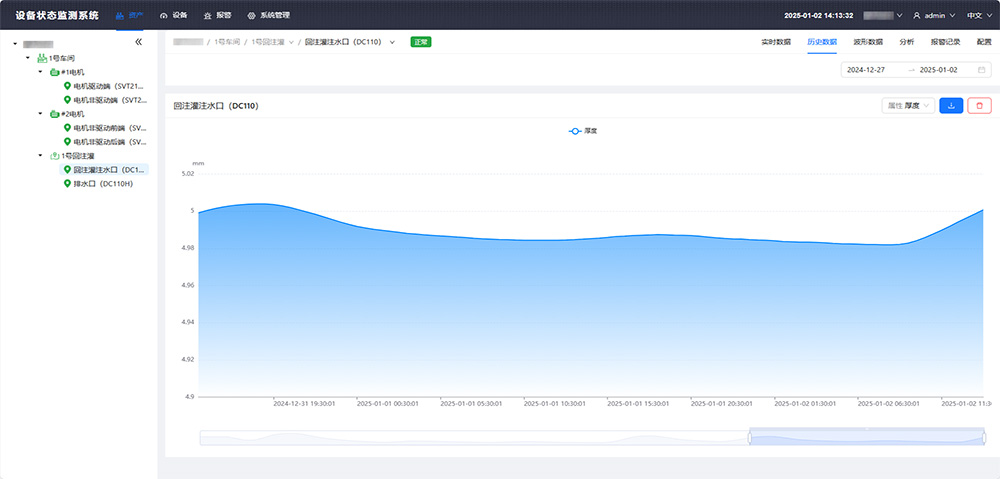

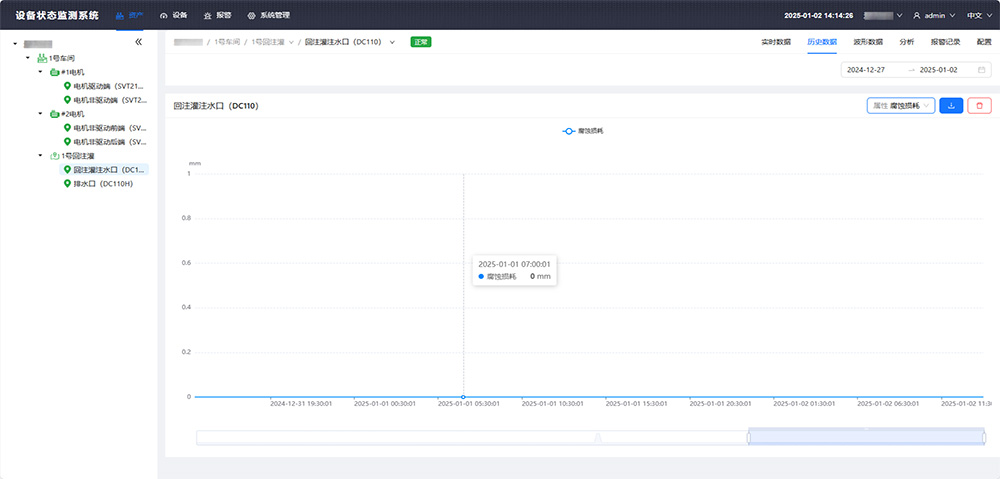

Tracks variations in wall thickness across pipelines and vessels to identify early warning signs.

Monitors real-time changes in corrosion rates for operational insights.

Displays cumulative corrosion loss at each monitoring point to ensure long-term safety.

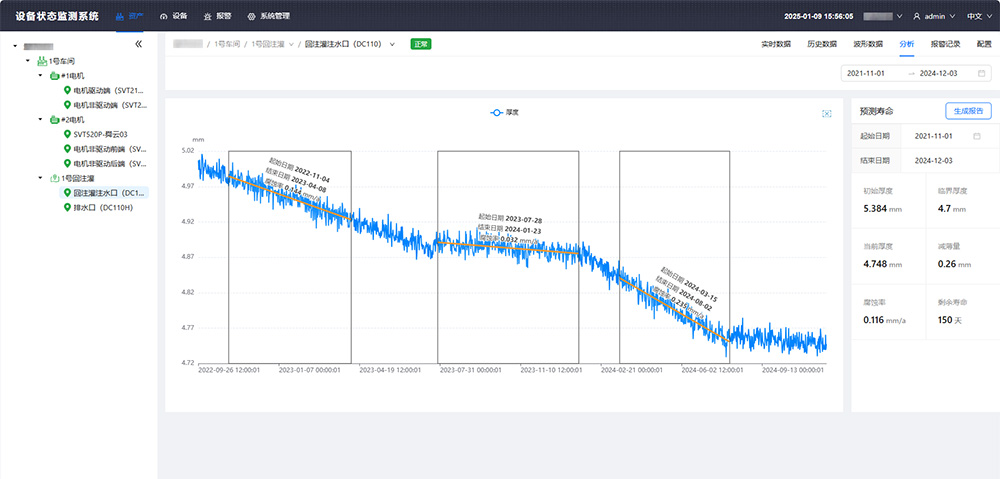

Offers detailed visual reporting on corrosion rate calculations, trend predictions, and remaining life estimations.

The Theta Corrosion Monitoring System enables oil, gas, and chemical enterprises to transition from manual inspections to fully digital, intelligent asset management. With robust data processing, accurate remote monitoring, and a flexible architecture, the system significantly enhances equipment safety, reliability, and maintenance efficiency. It extends asset life, reduces maintenance costs and operational risks, and delivers measurable value in both safety and economics.

Submission