News Center

Stay up to date with Theta’s latest innovations and progress

Search the whole station

Stay up to date with Theta’s latest innovations and progress

As China’s wind power installations rapidly expand inland, the structural reliability of turbine foundations has become a growing concern. Although most turbines are designed for a 20-year service life, some units have experienced fatigue-related foundation issues within the first 2–5 years of operation, occasionally resulting in full disassembly and reconstruction—leading to severe financial losses.

Among the most common root causes is the loss or failure of preload in foundation anchor bolts, which can trigger turbine shutdowns and compromise structural integrity. To address this challenge, Theta has launched a practical, intelligent solution for monitoring foundation anchor bolts in wind turbines.

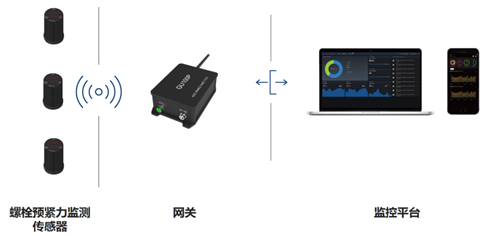

System Architecture

The solution comprises the SAS100A wireless preload sensors, GU100P gateway, and a centralized monitoring server. The ultrasonic-based sensor is mounted on the bolt’s end face and calculates elongation by measuring changes in ultrasonic wave travel time under different preload conditions—allowing real-time, non-invasive preload evaluation.

In case of bolt fracture, the system detects echo anomalies and determines the break point location by comparing actual versus measured bolt length.

Data is transmitted via Theta’s low-power wireless network to a GU100P gateway installed inside the turbine tower, then relayed to the wind farm’s central control system via fiber optics.

Real-World Application

At a wind farm in Inner Mongolia, Theta deployed the solution on several turbines with 4-meter M42 foundation bolts. Each bolt was equipped with the SAS100A wireless preload sensor, enabling real-time monitoring of preload force, microcracks, elongation, and temperature.

The system’s ultra-low power design and robust communication performance made it well-suited for the harsh environmental conditions of the site.

Value and Impact

This wireless system enables real-time monitoring of multi-meter anchor bolts, detecting preload loss, fracture, or loosening trends well in advance. It triggers alerts and maintenance recommendations based on trend analysis, helping to reduce manual inspections, lower operational costs, and extend turbine service life.

With precise diagnostics and predictive capabilities, Theta’s solution significantly improves operational reliability while minimizing unplanned downtime and structural failure risks.

Submission