News Center

Stay up to date with Theta’s latest innovations and progress

Search the whole station

Stay up to date with Theta’s latest innovations and progress

In large-scale steel manufacturing, motors are critical rotating machines whose operational stability directly affects production continuity. Vibration is a key indicator of a motor’s health—excessive or increasing vibration often signals internal faults such as imbalance, wear, misalignment, or fatigue, which, if undetected, can lead to costly downtime or even serious equipment failure.

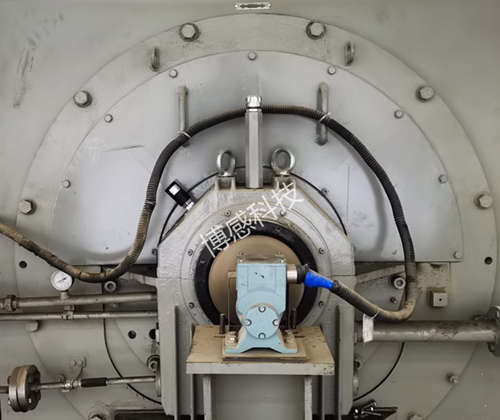

To address this, Theta deployed its wireless vibration and temperature monitoring system to key motors within a steel plant. The system utilizes the SVT210 wireless vibration and temperature sensor, which is installed non-invasively using a magnetic base and M8 bolt. It captures multi-dimensional vibration features (including acceleration, velocity, displacement) and temperature data at regular intervals. The sensor also supports ISO vibration alert thresholds and allows custom settings for flexible fault detection. The sensor transmits data wirelessly to the GU100P gateway, which is installed inside a control cabinet. The gateway uses a 4G connection to upload data to ThetaCloud, our cloud-based IoT platform. ThetaCloud offers remote equipment management, waveform visualization, historical trend analysis, and predictive maintenance capabilities powered by intelligent analytics.

Key Advantages of the Solution:

This wireless system enables early fault detection and predictive maintenance for motors, significantly reducing unplanned downtime, maintenance costs, and operational risk

Submission