Product Center

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

Search the whole station

Professional sensing solutions for equipment monitoring—empowering sensor, edge, cloud,

and AI to enhance industrial efficiency and safety

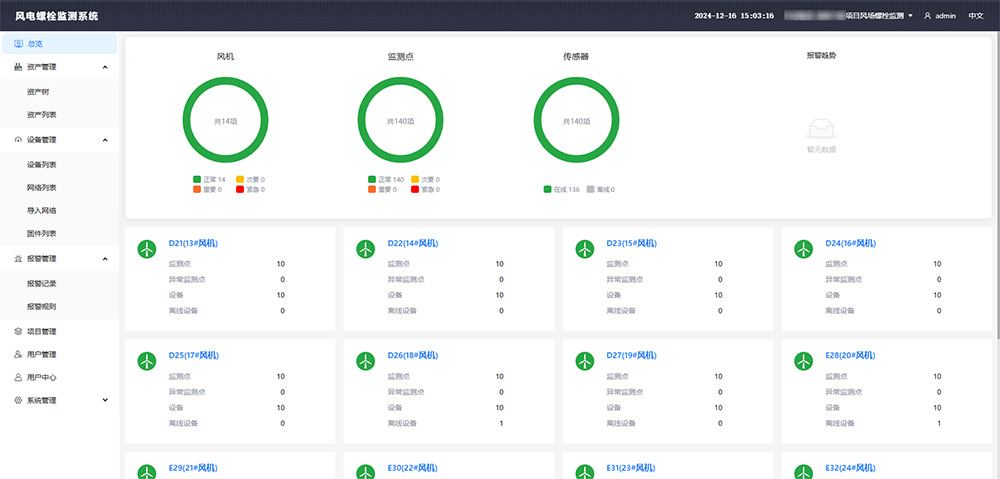

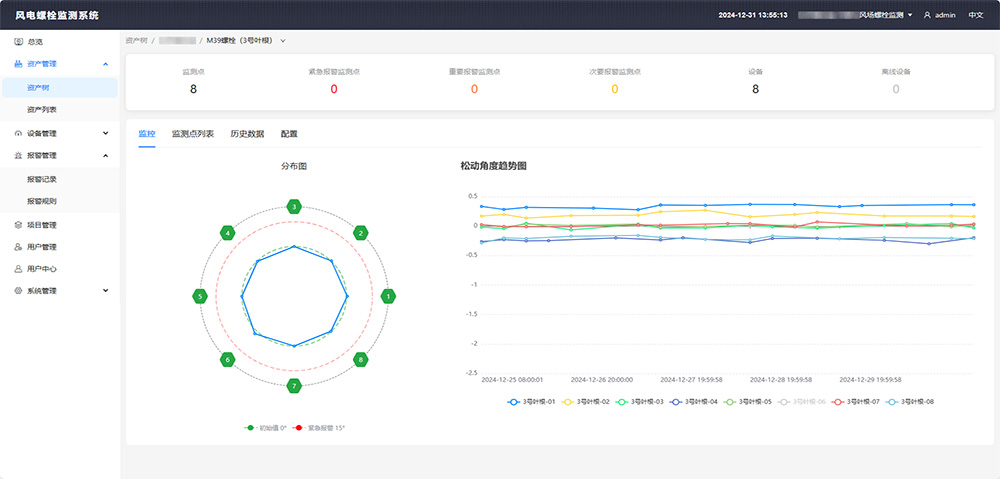

The Theta Wind Turbine Bolt Monitoring System is an industrial software solution specifically designed for monitoring bolts in wind turbines. Based on IoT technology and compatible with both Linux and Windows operating systems, the system supports B/S (browser/server) architecture. It communicates via fiber-optic ring networks within the wind farm to collect real-time data from turbine gateways, including bolt loosening angles and preload force. Beyond comprehensive bolt management, the system offers features such as bolt ID assignment, initial value calibration, graphical data visualization, and status alarms. This enables users to effectively monitor equipment health, prevent failures, optimize maintenance strategies, and improve the operational efficiency and reliability of wind turbines.

Displays the overall health condition of all monitored bolts across the turbine.

Tracks bolt loosening trends in real time to identify potential risk patterns.

Monitors preload changes to ensure bolts remain within safe tension thresholds.

Visualizes the spatial distribution and health of monitored bolts across the turbine structure.

The deployment of Theta’s Wind Turbine Bolt Monitoring System marks a major step in the transition from scheduled maintenance to intelligent operations in the wind energy sector. Combining proprietary sensor technology, efficient data processing, accurate remote diagnostics, and a flexible architecture, the system provides a unified smart solution. It significantly enhances the safety, reliability, and maintenance efficiency of wind turbines while supporting the broader digital and intelligent transformation of the wind power industry.

Submission