News Center

Stay up to date with Theta’s latest innovations and progress

Search the whole station

Stay up to date with Theta’s latest innovations and progress

Theta has recently completed the pilot installation of a turnout bolt loosening monitoring system on a key urban rail section, marking another milestone in the company’s advancement in smart transportation infrastructure. The system has been fully commissioned and recognized by the client, with plans now underway for broader deployment across additional sites.

Urban rail transit plays a vital role in modern city operations, and track safety remains paramount. By the end of 2020, China had built the world’s largest urban rail network, with over 7,978 kilometers of operational track. As train speeds, axle loads, and network densities increase, the mechanical integrity of fastening components—especially bolts—has become a growing concern for railway safety.

Turnouts (track switches) are among the most structurally complex components of the rail network. They are subjected to high dynamic loads and repetitive mechanical stress, making their bolts particularly vulnerable to loosening and fatigue failures. Without timely detection, such failures can lead to misalignment, derailment, or catastrophic accidents. Traditional manual inspection methods are labor-intensive, error-prone, and lack real-time insights, underscoring the urgent need for intelligent monitoring solutions.

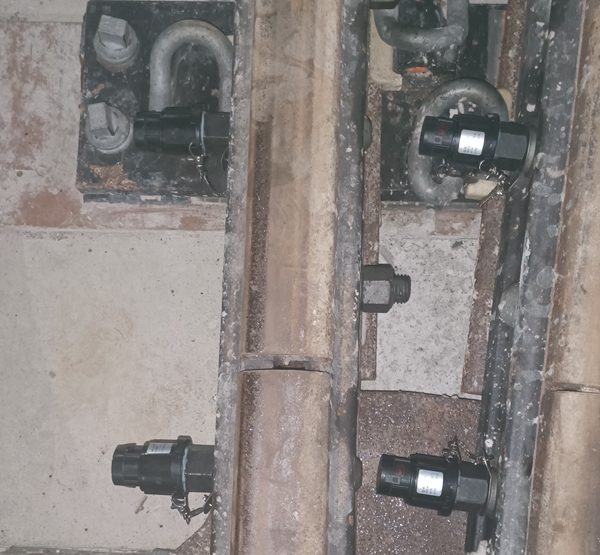

To address this challenge, Theta has introduced a wireless bolt loosening monitoring system based on its proprietary ultra-low-power sensing technology. For this pilot project, the SA210 wireless angle sensor was deployed to monitor the rotation angle of turnout bolts in real time. The system is designed for rapid, non-intrusive installation, requiring no wiring and ensuring minimal disruption to railway operations.

Each sensor transmits data wirelessly to a nearby gateway, which then uploads information to the cloud platform via a 4G network. The platform provides real-time status visualization, historical trend analysis, and automated alerts, enabling maintenance teams to remotely monitor the condition of turnout bolts and act before faults escalate.

In response to the harsh vibration and environmental demands of rail applications, Theta also enhanced the mechanical structure of the sensor, adding anti-loosening components and safety chains to ensure long-term reliability under high-frequency stress.

The success of this pilot installation demonstrates Theta’s commitment to improving rail safety through smart sensing solutions. By enabling predictive maintenance and reducing dependence on manual inspection, the system helps rail operators increase operational reliability, cut maintenance costs, and prevent safety incidents.

Theta will continue to collaborate with industry partners to expand the deployment of intelligent monitoring systems and drive the digital transformation of rail infrastructure.

Submission